The manufacturing trade is on the forefront of technological evolution, embracing improvements that streamline operations, improve high quality, and scale back prices. Amongst these, pc imaginative and prescient has emerged as a pivotal know-how, leveraging huge volumes of visible knowledge to drive actionable insights and automation. Powered by developments in synthetic intelligence (AI), machine studying (ML), and deep studying (DL), pc imaginative and prescient allows machines to carry out duties historically reliant on human notion.

This weblog explores how pc imaginative and prescient transforms manufacturing via superior functions, technical workflows, and real-world examples.

What’s Laptop Imaginative and prescient?

At its core, pc imaginative and prescient entails enabling machines to interpret and course of visible knowledge—pictures, movies, or 3D environments—to extract significant insights. That is achieved via subtle algorithms and AI frameworks, corresponding to convolutional neural networks (CNNs) and imaginative and prescient transformers (ViTs). These techniques mimic the way in which people acknowledge patterns and make selections primarily based on visible inputs however achieve this with enhanced precision, scalability, and pace.

Key Elements of Laptop Imaginative and prescient in Manufacturing

Picture Acquisition: Capturing knowledge via high-resolution cameras, LiDAR sensors, or hyperspectral imaging gadgets.Preprocessing: Methods like noise discount, picture normalization, and knowledge augmentation guarantee clear and usable enter knowledge.Function Extraction: Utilizing algorithms like Scale-Invariant Function Rework (SIFT) or Histogram of Oriented Gradients (HOG) to determine important picture options.Mannequin Inference: Deep studying fashions corresponding to YOLO (You Solely Look As soon as) or Quicker R-CNN for object detection, segmentation, or classification.Submit-Processing and Evaluation: Decoding mannequin outputs to drive actionable insights and real-time decision-making.

Functions of Laptop Imaginative and prescient in Manufacturing

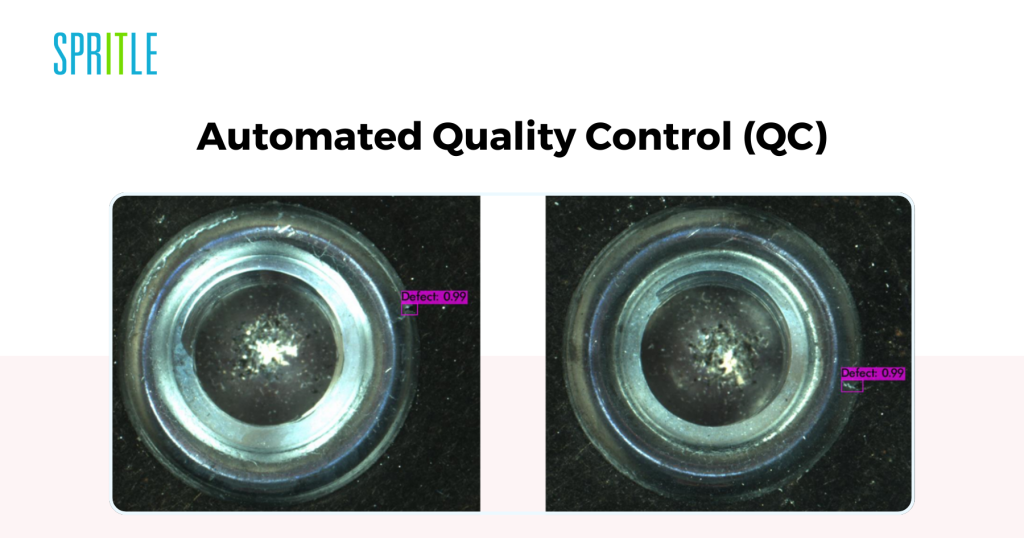

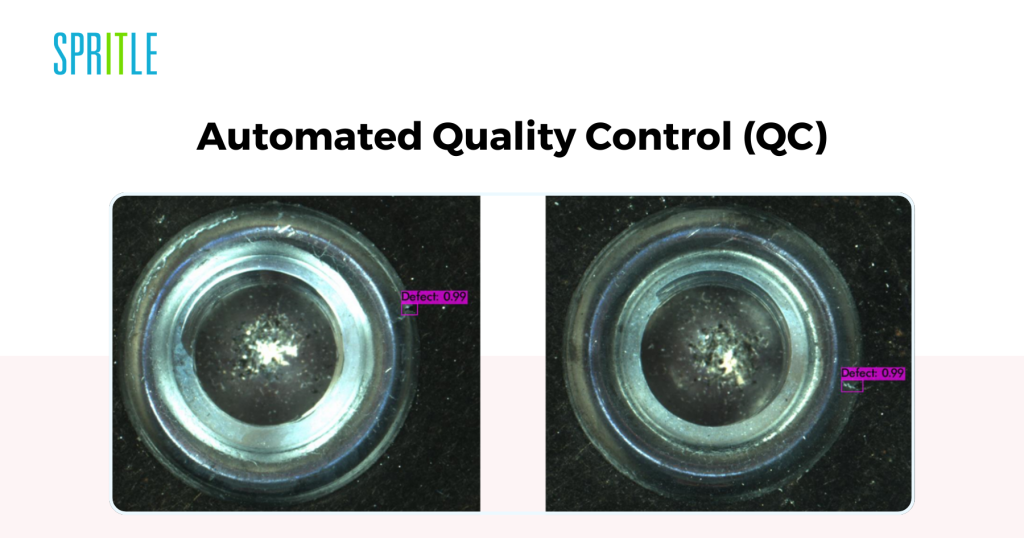

1. Automated High quality Management (QC)

Conventional QC processes typically rely upon guide inspection, which is time-intensive and susceptible to errors. Laptop imaginative and prescient techniques automate this by:

Defect Detection: Utilizing picture segmentation and anomaly detection algorithms to determine cracks, scratches, or discolorations. Superior methods like semantic segmentation guarantee pixel-level accuracy.Dimensional Verification: Using 3D imaginative and prescient techniques to measure tolerances and guarantee compliance with CAD designs.Excessive-Velocity Inspection: Programs like Cognex In-Sight can examine a whole lot of things per minute, making certain high quality with out interrupting manufacturing movement.

As an illustration, semiconductor producers use imaginative and prescient techniques to detect micro-level defects in silicon wafers, leveraging CNNs educated on 1000’s of defect patterns.

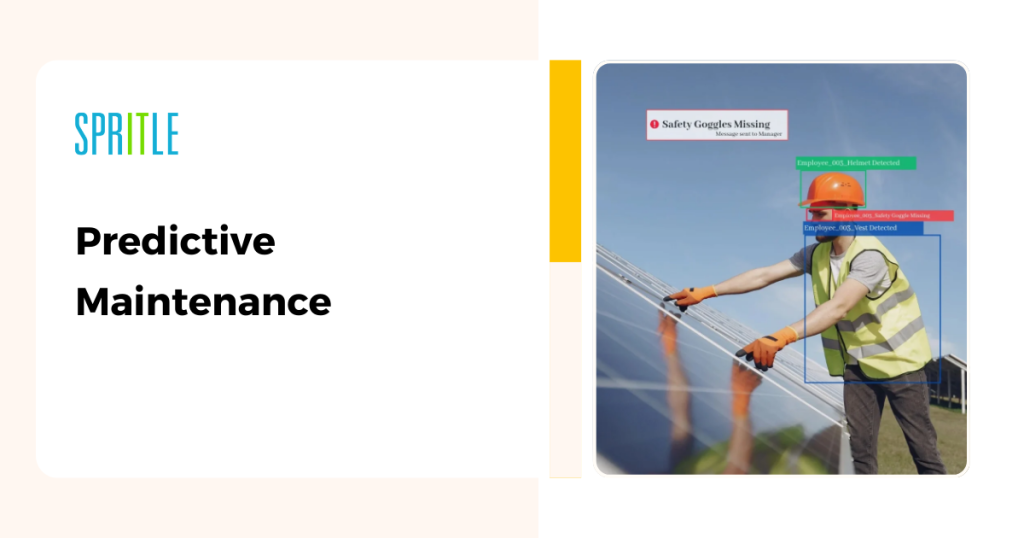

2. Predictive Upkeep

Unscheduled downtime can value producers tens of millions yearly. Laptop imaginative and prescient facilitates condition-based upkeep by analyzing visible knowledge from equipment.

Thermal Imaging: Detects overheating elements utilizing infrared cameras, flagging potential failures.Vibration Evaluation: Excessive-speed cameras observe deviations in movement patterns, predicting mechanical faults.Put on Monitoring: Imaginative and prescient techniques seize minute put on patterns on instruments, enabling replacements earlier than breakdowns.

A sensible instance is Airbus, which employs drones outfitted with imaginative and prescient techniques to examine plane for structural anomalies, lowering upkeep instances by over 90%.

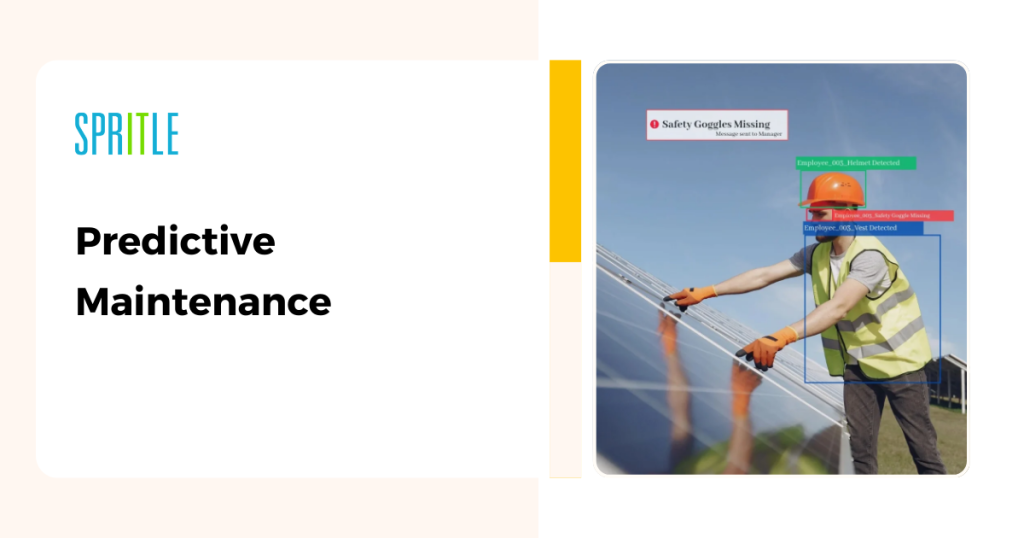

3. Employee Security and Compliance

Making certain employee security in hazardous environments is a precedence. Laptop imaginative and prescient improves security compliance via:

PPE Detection: Fashions educated on datasets like Open Photos or customized datasets detect whether or not staff put on security gear, corresponding to helmets or gloves, in real-time.Behavioral Evaluation: Cameras monitor actions, figuring out unsafe practices corresponding to proximity to harmful equipment or unauthorized zones.Incident Detection: Programs detect emergencies like fires, spills, or collapses and set off automated alerts.

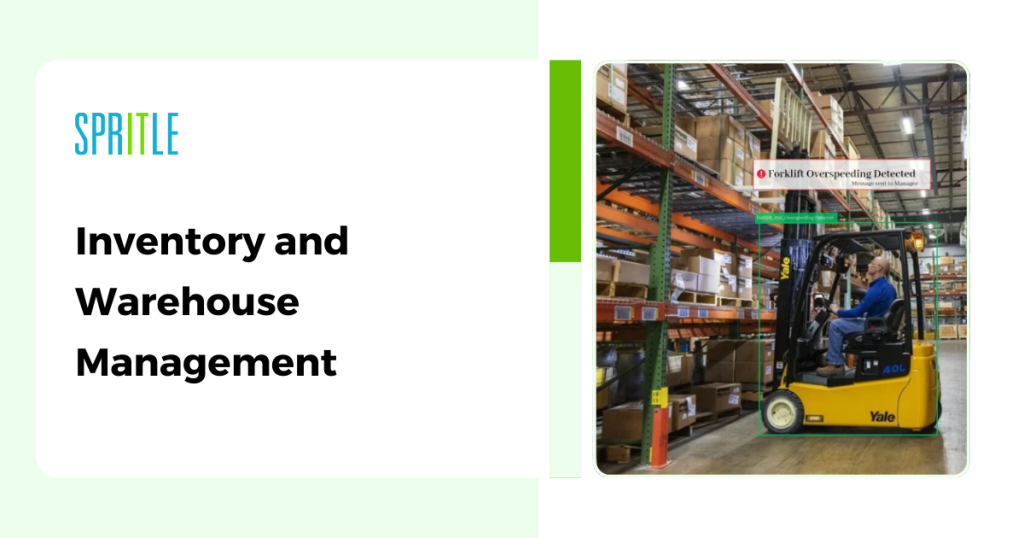

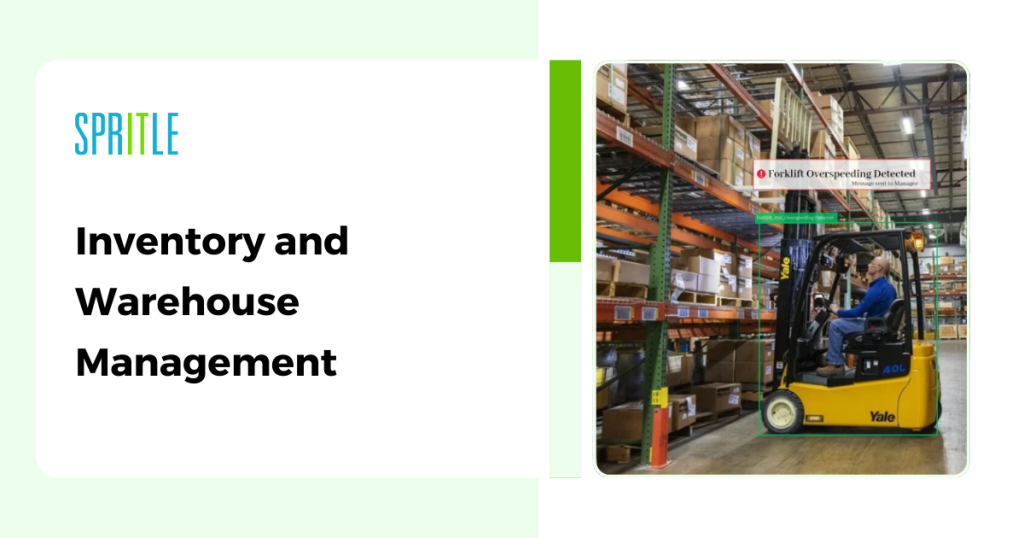

4. Stock and Warehouse Administration

Environment friendly stock administration is crucial for uninterrupted manufacturing. Laptop imaginative and prescient enhances logistics with:

Actual-Time Monitoring: Imaginative and prescient-guided robots navigate warehouses, scanning barcodes or QR codes to replace stock techniques.Shelf Monitoring: Cameras mixed with object recognition observe inventory ranges, robotically alerting for restocking.Load Verification: Imaginative and prescient techniques verify that packages are precisely labeled and loaded for cargo, lowering errors.

A number one instance is Amazon’s achievement facilities, the place pc vision-guided robots collaborate with people to streamline warehouse operations.

5. Course of Optimization and Robotic Integrations

Laptop imaginative and prescient seamlessly integrates with robotics to optimize manufacturing processes. Use circumstances embody:

Collaborative Robots (Cobots): Cobots outfitted with imaginative and prescient techniques deal with advanced duties like meeting, welding, or materials dealing with whereas adapting to dynamic circumstances.Actual-Time Suggestions: Imaginative and prescient techniques monitor manufacturing traces, figuring out bottlenecks and offering knowledge to refine workflows.AI-Powered Sorting: Automated techniques kind merchandise by measurement, colour, or form, typically utilizing reinforcement studying for steady enchancment.

Tesla’s Gigafactories make use of vision-guided robotics extensively, optimizing car meeting with minimal human intervention.

Technical Workflow of Laptop Imaginative and prescient in Manufacturing

The implementation of pc imaginative and prescient follows a structured workflow:

Knowledge Assortment:Set up high-resolution cameras and sensors to seize visible knowledge.Use distributed edge gadgets for native processing or centralized cloud techniques for advanced analyses.Mannequin Growth:Select acceptable AI fashions primarily based on the duty (e.g., ResNet for picture classification, Masks R-CNN for segmentation).Prepare fashions on various datasets utilizing frameworks like TensorFlow or PyTorch.Increase datasets with artificial pictures to enhance robustness.Deployment:Use edge AI gadgets like NVIDIA Jetson for low-latency duties or cloud platforms like AWS for large-scale processing.Implement APIs to combine imaginative and prescient techniques with Manufacturing Execution Programs (MES) or Enterprise Useful resource Planning (ERP) software program.Steady Enchancment:Monitor mannequin efficiency metrics corresponding to precision, recall, and latency.Replace fashions frequently to adapt to new manufacturing eventualities or defect patterns.

Challenges and Future Instructions

Key Challenges

Knowledge Quantity and High quality: Capturing high-quality, labeled datasets is resource-intensive.Integration Complexity: Aligning imaginative and prescient techniques with legacy manufacturing processes will be difficult.Actual-Time Processing: Attaining low-latency inference, particularly in high-speed environments, requires sturdy edge computing infrastructure.

Future Instructions

Edge AI Enlargement: On-device processing with minimal latency will drive functions in real-time high quality management and security monitoring.3D Imaginative and prescient Programs: With developments in LiDAR and stereoscopic imaging, producers can obtain larger depth notion and accuracy.Explainable AI (XAI): As AI-driven imaginative and prescient techniques change into important to decision-making, making certain transparency and trustworthiness will acquire significance.Integration with Digital Twins: Laptop imaginative and prescient will increase digital twin fashions, offering real-time suggestions for simulations and course of optimizations.